Swimming Pool Construction Specfication

Lifestyle

takes pride in its No Compromise approach

to its swimming pool shell construction.

The MOST important factor of any swimming pool is the specification

and the way in which the shell is formed.

An important point to note, is that our typical pool shell is traditional

and accurate in section and dimension with a shallow

end, slope and deep end. The walls are vertical and extend to full

depth of the deep end with a 300mm radius at the wall floor joint.

This configuration gives a greater volume of swimming area, against

the cost-saving hopper or bowl type commonly found in the market

place.

This traditional style of pool allows us to complete a craftsman-like

finish to our mosaic tiling, without the need to make

unsightly cuts and seams in the finished surface.

Our pools shells conform to rigorous BS 8007 standards

and are covered by full

10 year warranty.

|

1. |

Following the accurate excavation, sub floor preparation with

porous 100mm layer of dry-lean concrete and any necessary underpool

drainage works, the shape of the pool is formed with a lightweight

shuttering, to exact dimensions required. At this stage, we

incorporate any features such as level deck overflow, balance

tanks, automatic pool cover housings, integrated Spa units,

steps, seats or any other relevant design feature. There is

no limitation to the shape we can provide. |

|

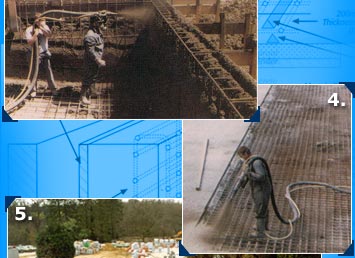

2. |

The

next stage is to fix the steel reinforcement to the individual

required specification. This singularly is the most IMPORTANT

part of shell construction and is the very backbone of the pool

itself. We can design the pool shell simply to support the walkway

around the pool or even the pool enclosure itself.

|

|

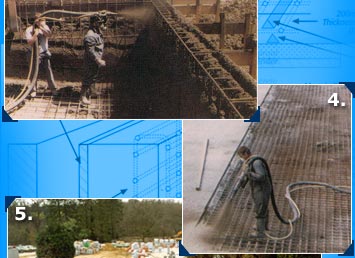

3./4. |

Finally

the shell is completed by applying a special mix of sprayed

concrete at high velocity to specified minimum structural thickness

and accurately finished by hand. This process can take one or

many days, dependent on the size or complexity of the pool,

curing to an immense compressive strength of 35 Newtons.

|

|

5.

|

The

entire pool shell construction is carried out by our own in-house

subsidiary company Guntek Ltd, enabling us to guarantee the

highest possible standard of workmanship at this crucial stage. |

|

|

On

completion of the pool shell, the shuttering is removed allowing

our engineers to install and test the circulation pipework and

necessary services.

The pool shell is now ready for its final coats of waterproof

render and mosaic tiles.

|

|